intdash Automotive Pro

Contents of the intdash Automotive Pro package service

intdash Automotive Pro

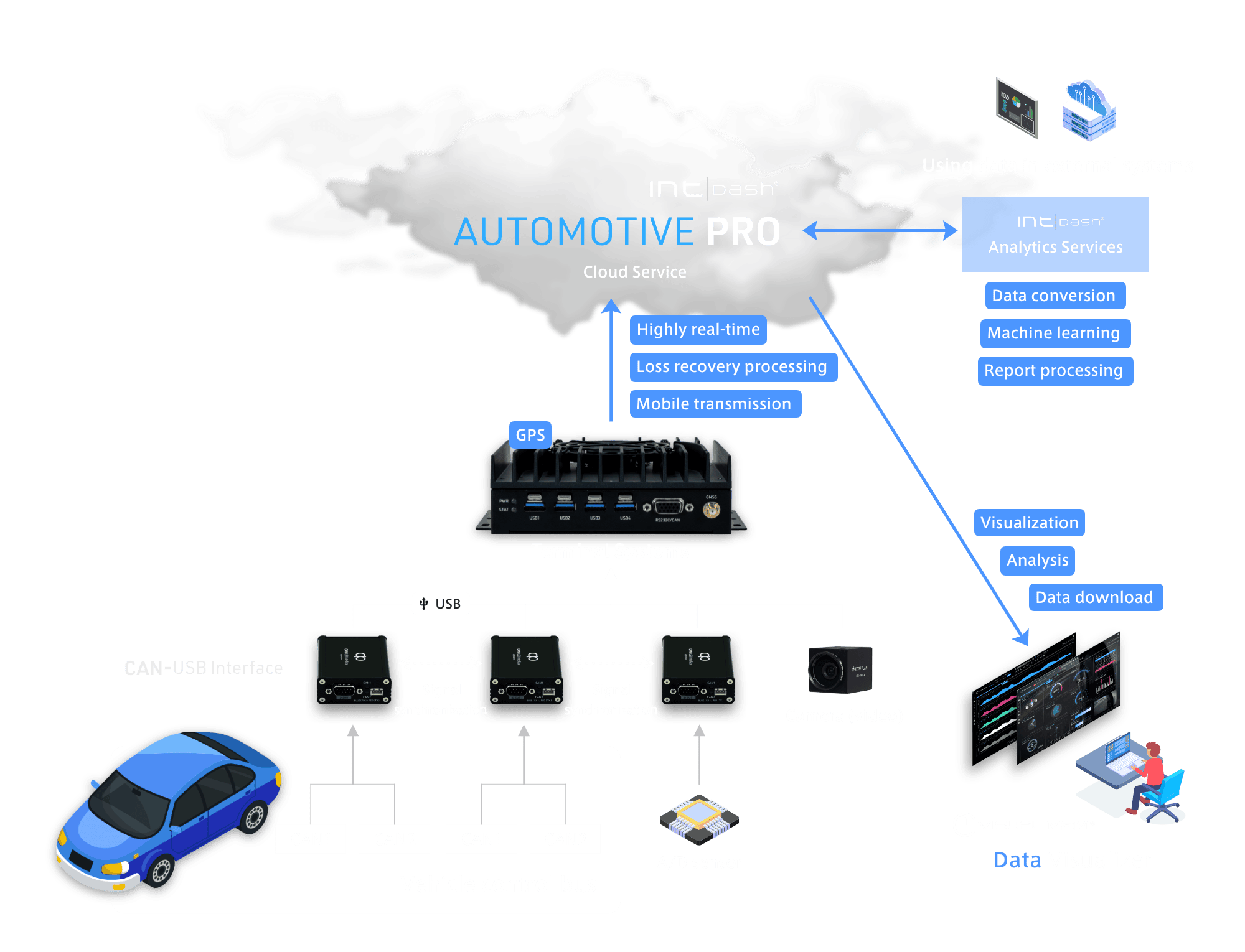

intdash Automotive Pro is a SaaS package for automobile measurement that uses intdash as the back-end system. The combination of the dedicated in-vehicle device, Terminal System, and CAN-USB Interface makes the integration of data timestamps possible and allows for diverse measurements. A web-based dashboard application, Visual M2M Data Visualizer, assists data visualization, data analysis, and real-time data monitoring. The optional intdash Analytics Services allows you to implement analysis data conversion, reporting, and machine learning.

intdash Automotive Pro is a cloud-based SaaS solution that provides a one-stop workflow in the automotive industry including logging of vehicle CAN (Controller Area Network) data and sensor data, data management, visualization, and analysis.

Benefits

- Remote automatic data collection reduces the time and effort of data sampling.

- Users at many sites can access the system at the same time to view real-time data and analyze accumulated data.

- Any PC with a browser can be used (HTML5-enabled browser required).

- Data can be analyzed from a variety of viewpoints using data stream display, graphs, and CSV.

- Data security of communications between vehicles and viewers to protect confidentiality

- Data processing for analysis, machine learning, and reporting with Analytics Services (optional)

Terminal Systems

In-vehicle terminal system for remote, automatic, and real-time data measurement

EDGEPLANT T1 APPLIANCE (NVIDIA® Jetson™ TX2)

- All-in-one design for IoT with built-in SIM slot and GPS.

- Highly reliable hardware that can be used as an in-vehicle embedded computer.

- Wide power supply voltage specification (9 to 36V) allows safe use in commercial vehicles and construction machinery as well as passenger cars.

- Compliant with EMC standards (E-mark) required for in-vehicle equipment, suppressing noise propagation to peripheral devices and vehicle power systems and achieving high immunity performance.

- Wide operating temperature range (-20°C to +65°C).

- Multiple camera inputs and encoding processing are possible.

Utilities to support measurements

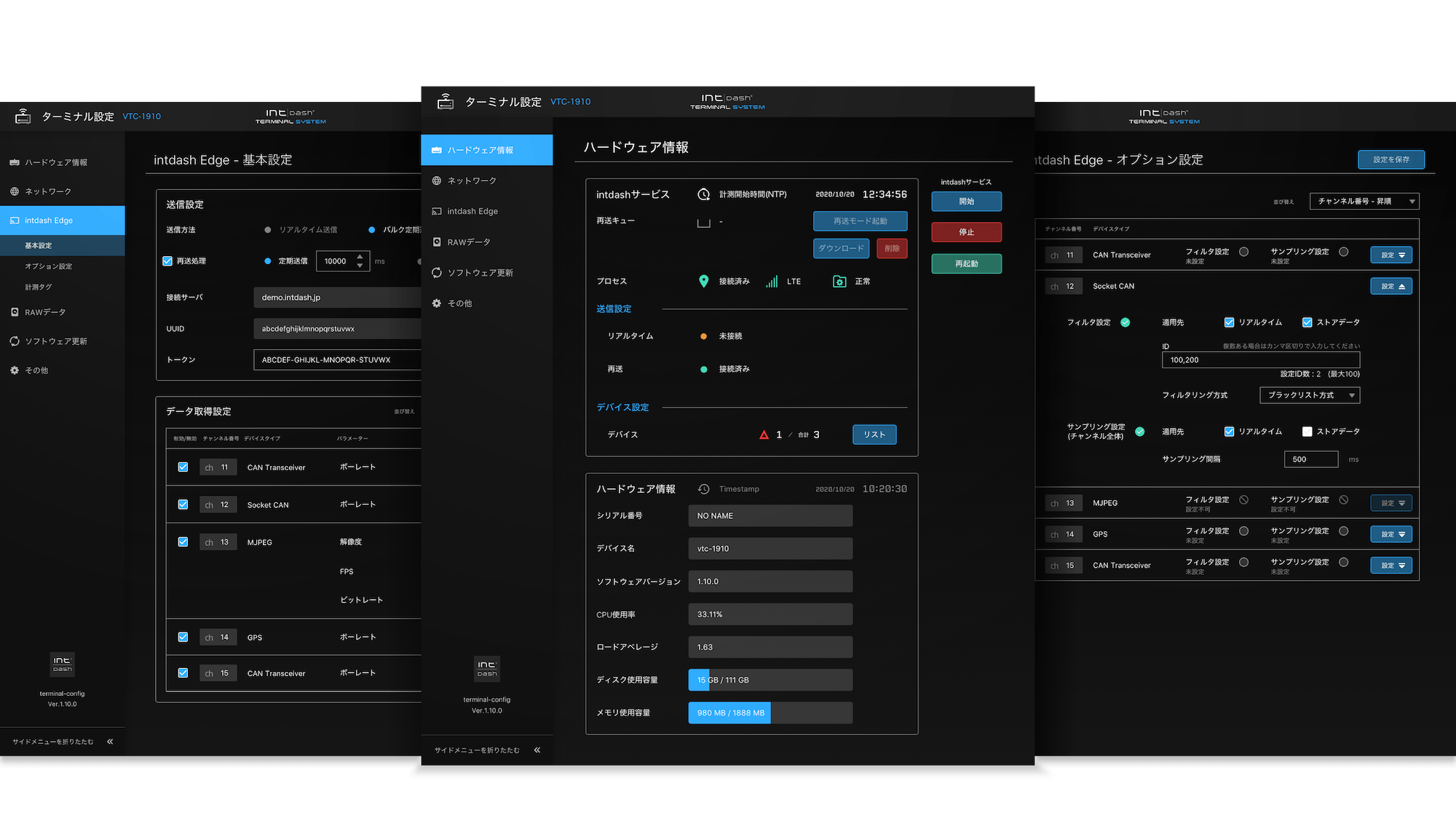

Terminal Config

- Browser-based setting tool

- Wi-Fi or LAN connection from the PC to the in-vehicle terminal

- Status check of in-vehicle terminal

- Sampling settings for sending data

- Filter settings for sending data

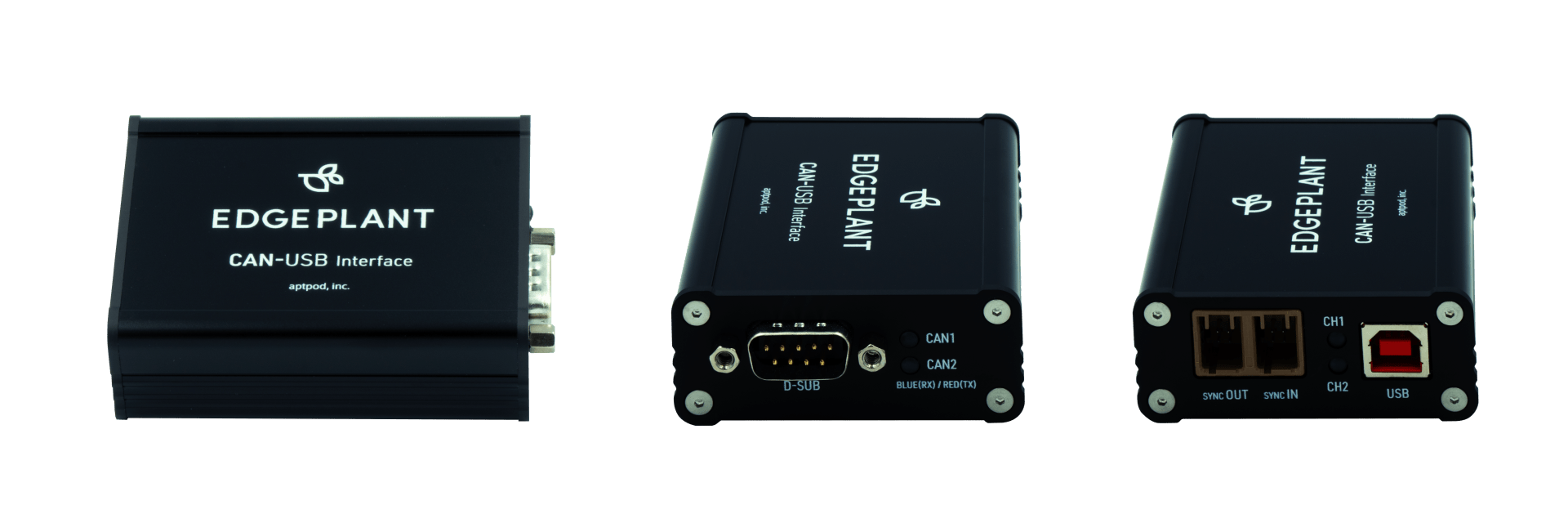

CAN-USB Interface

CAN-USB interface that supports two CAN bus channels

- Support of two CAN bus channels

- Timestamp processing for CAN data

- Signal synchronization among multiple instruments

- Signal synchronization with external measuring devices or other equipment

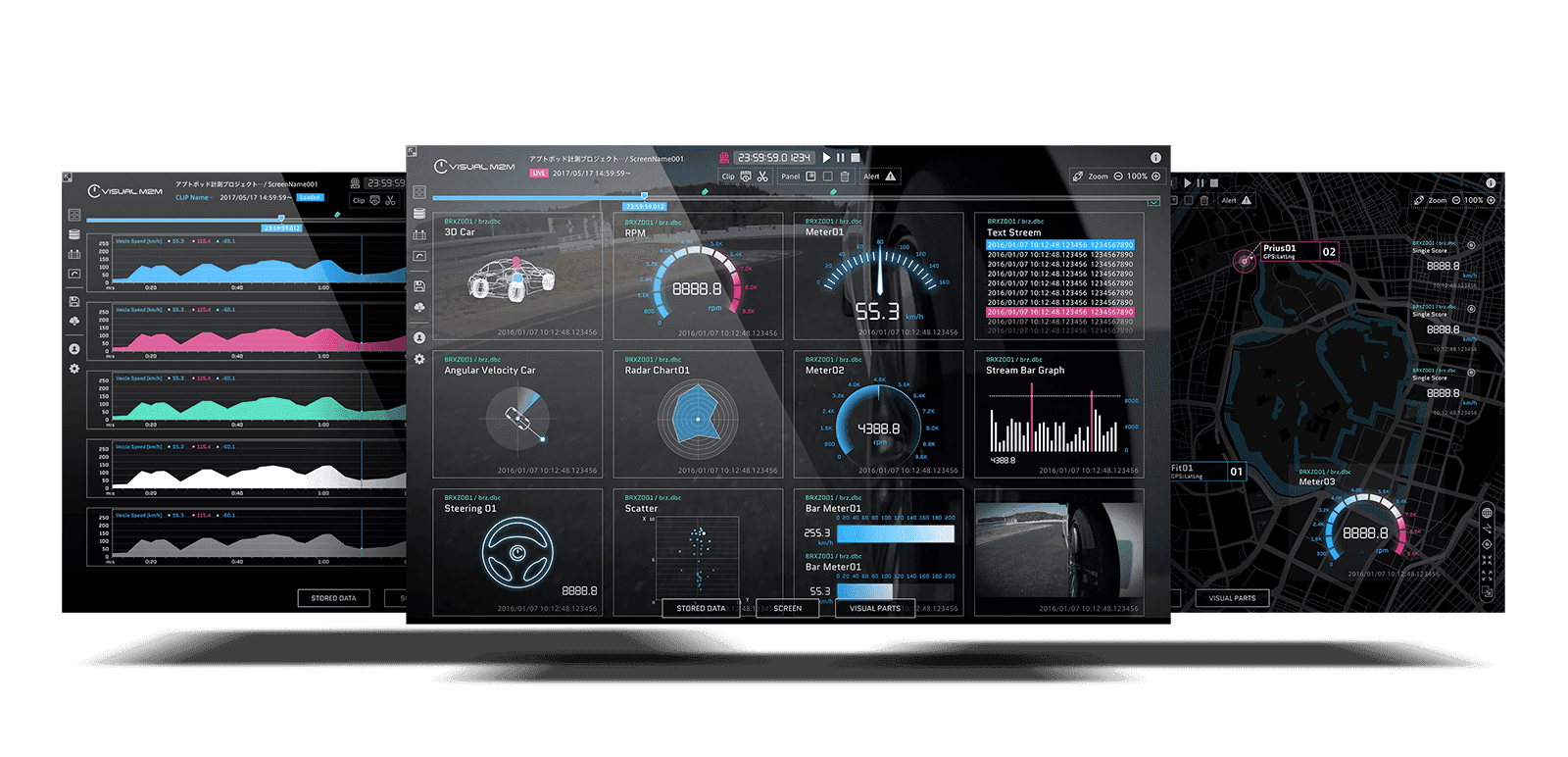

Data Visualizer

Intuitive browser-based user interface with excellent design

- Functions required for data analysis including data stream playback, analysis graph, and CSV download are provided.

- Users at many sites can access the system at the same time to view real-time data and analyze accumulated data.

Beautiful data visualization anywhere with a browser

Data Visualizer provides a browser-based UI leveraging HTML5. The user can easily create a dashboard and visualize data from various angles with intuitive drag & drop operation.

- Data visualization with a variety of visual parts

- Statistics graphs (such as histograms and scatter diagrams)

- Real-time statistics display

- Data display with 2D or 3D models

- Loading of video data

- Parallel and background display of video data and measurement data

- Conversion of binary data into physical values using a CAN database (dbc file)

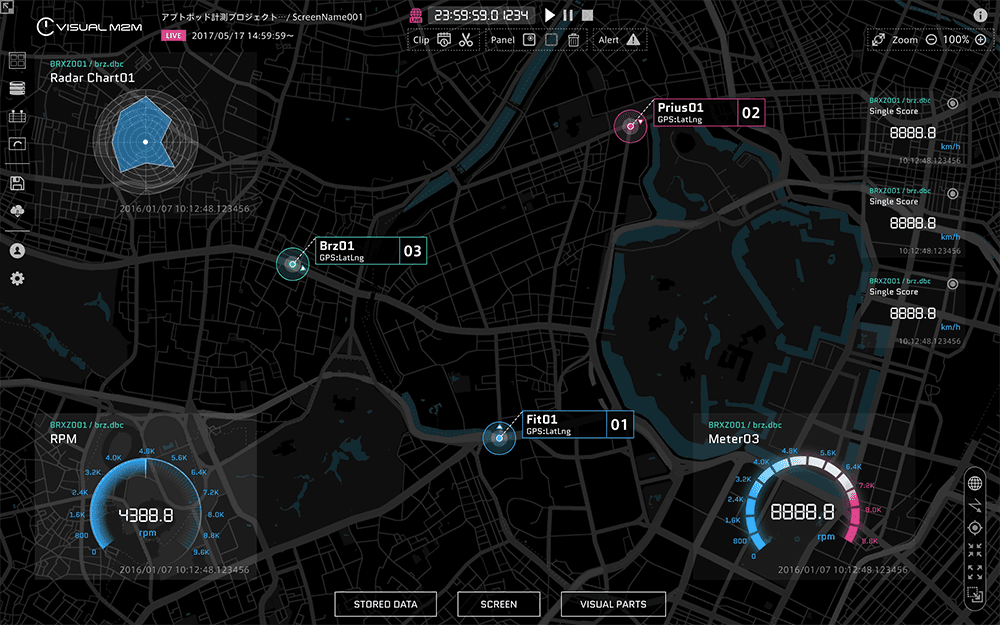

- GPS data mapping

- Vehicle fleet display

- Trajectory display on the map

- Parallel and background display of map data and measurement data

- Display of events (such as errors and values above the threshold) on the trajectory on the map